E 6800 Cartridge heater

Quick and targeted heating for your application.

Our stainless steel cartridge heaters offer the best combination of characteristics for optimum heat conduction, high corrosion resistance and appropriate thermal expansion. The precisely ground outer diameters ensure perfect installation in the appropriate hole depending on the surface load. In addition, the high-precision ground surface allows optimum heat dissipation to the mould which increases service life as well as efficiency.

Applications

- For increasing flow line strength

- For heating thermosetting plastics and elastomer moulds

- Mould heating for variotherme process

- Other applications where high heating power is required

Installation

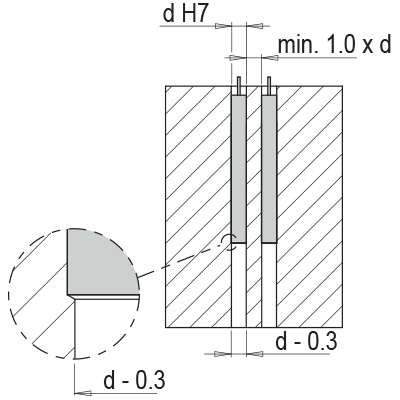

Cartridge heaters with a surface load of up to 20 W/cm² require a H7 hole.

Cartridge heaters which have a higher surface load need to have a press fit to ensure good heat dissipation from the cartridge heater and thus a long service life.

Important!

Do not use conductive sprays or pastes near the connection area.

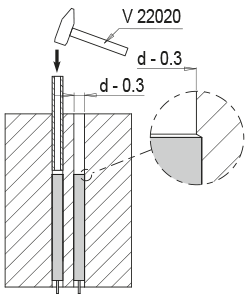

Removal

For the easiest possible removal, we recommend an offset hole which is 0.2 to 0.3 mm smaller than the cartridge heater diameter.

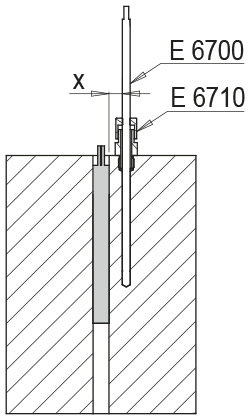

Position of the thermocouple

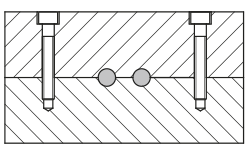

For good process control and to ensure that the required temperature is reached, the thermocouple should be positioned close to the object to be heated. In addition, to protect the cartridge heater from overheating and ensure a long service life, the thermocouple is ideally mounted 10 mm away from the cartridge heater.

Often a compromise is necessary between these two requirements, which is usually made by averaging out the space and not using full power, and helps to ensure a long cartridge heater service life.

Calculation

For information on finding the right cartridge heater and quantity as well as calculation examples and other useful information, please refer to our fact sheet.

Operating the cartridge heater

Our profiTEMP+ device provides the ideal solution for monitoring and controlling the cartridge heaters with maximum process safety and reliable temperature control using state-of-the-art hardware and software components.

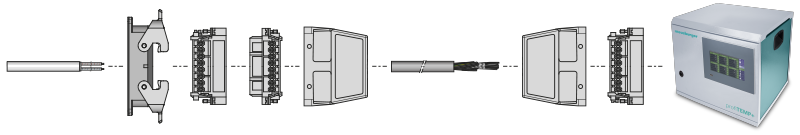

Connection scheme

A start-up circuit at the beginning of the process allows moisture to escape gently from the cartridge heaters, thus ruling out short circuit failures.

© 2022 by Meusburger Georg GmbH & Co KG | All rights reserved

© 2022 by Meusburger Georg GmbH & Co KG | All rights reserved

Česká republika [CS]

Česká republika [CS]

Danmark [DA]

Danmark [DA]

Deutschland [DE]

Deutschland [DE]

España [ES]

España [ES]

France [FR]

France [FR]

India [EN]

India [EN]

Italia [IT]

Italia [IT]

Magyarország [HU]

Magyarország [HU]

México [ES]

México [ES]

Nederland [NL]

Nederland [NL]

Polska [PL]

Polska [PL]

Portugal [PT]

Portugal [PT]

România [RO]

România [RO]

Schweiz [DE]

Schweiz [DE]

Slovenija [SL]

Slovenija [SL]

Srbija [SR]

Srbija [SR]

Suomi [FI]

Suomi [FI]

Sverige [SV]

Sverige [SV]

Türkiye [TR]

Türkiye [TR]

United Kingdom [EN]

United Kingdom [EN]

USA [EN]

USA [EN]

Österreich [DE]

Österreich [DE]

Ελλάδα [EL]

Ελλάδα [EL]

България [BG]

България [BG]

Росси́я [RU]

Росси́я [RU]

华 [ZH]

华 [ZH]